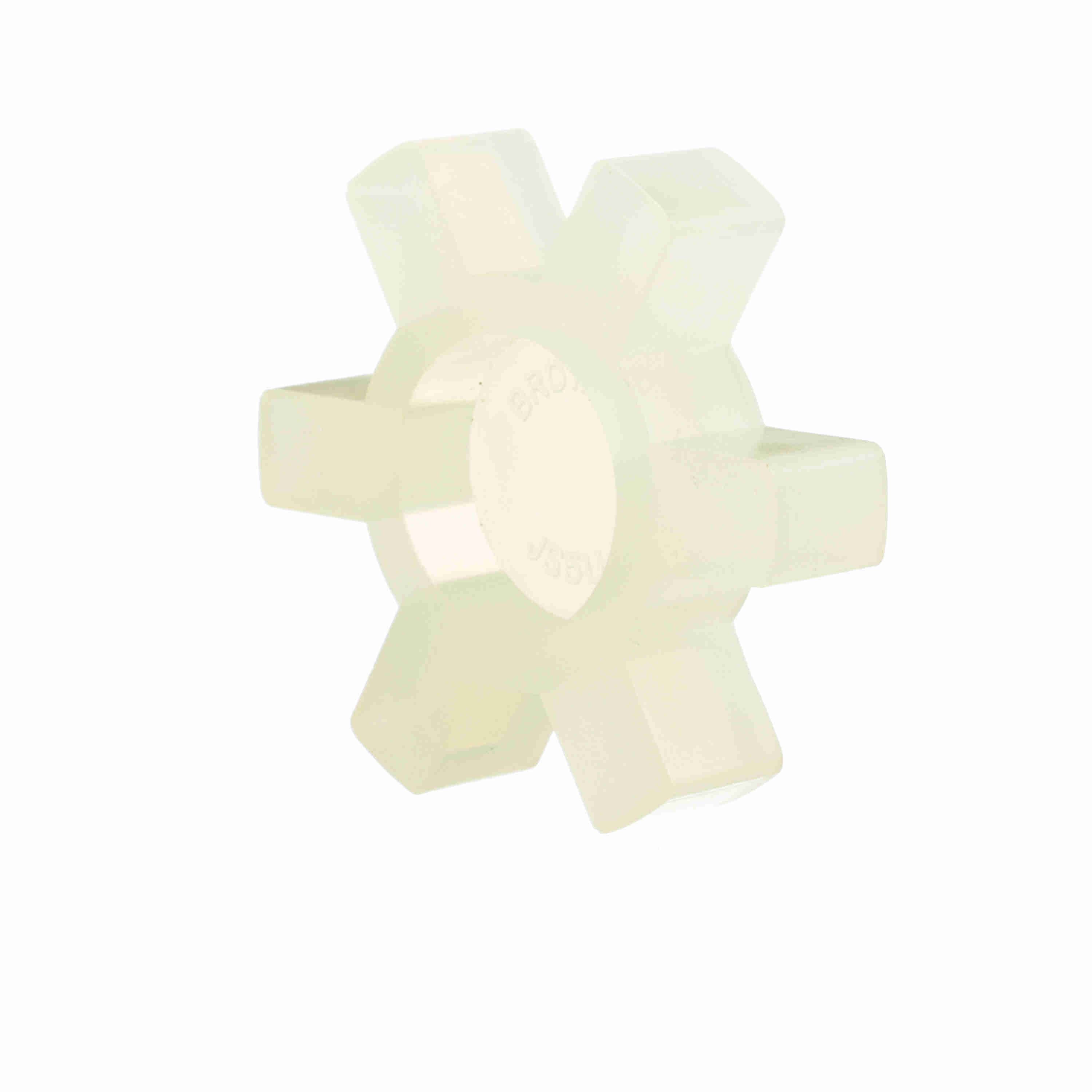

Jaw and wrap couplings are material flexing couplings that transmits torque through compression of an elastomeric spider insert placed between two intermeshing jaws.

Elastomeric Jaw and Wrap Couplings

KEY FEATURES

- Jaw Coupling

- Used with Bore Bushings

Elastomeric Jaw and Wrap Couplings

Browning Jaw Coupling Polyurethane Insert – Style JP5, JS5, JS5H

KEY FEATURES

- Jaw Style Coupling

- Polyurethane Insert

Elastomeric Jaw and Wrap Couplings

KEY FEATURES

- Non-Lubricated design for tough industrial applications.

- Maintenance savings through easily replaceable element in the application without moving the driving or driven equipment.

Elastomeric Jaw and Wrap Couplings

Kop-Flex Elastomeric Coupling – Style Standard (EE) – Size 6 – Finished Bore

KEY FEATURES

- Non-Lubricated design for tough industrial applications.

- Maintenance savings through easily replaceable rubber elements in the application, without moving the driving or driven equipment.

- Available close coupled or in various spacer configuration to suit pump applications.

- Easy to assemble and operate in hot, wet, gritty tough environment. Widely used in hot strip mill roller table application.

Elastomeric Jaw and Wrap Couplings

KEY FEATURES

- Non-Lubricated design for tough industrial applications.

- Maintenance savings through easily replaceable element in the application without moving the driving or driven equipment.

- Available close coupled or spacer configurations.

Tiếng Việt

Tiếng Việt