Regal Rexnord® brands are leading manufacturers of parallel-shaft gearboxes for the heavy-duty industrial market. These gearboxes feature rugged designs to meet every operating challenge, and they’re site proven in the world’s most demanding applications. They are application-engineered to minimize stress and wear and extend service life.

Parallel Shaft Gearing

Application-engineered to minimize stress and wear, to extend service life, and constructed to offer you maximum application flexibility.

Parallel Shaft Gearing

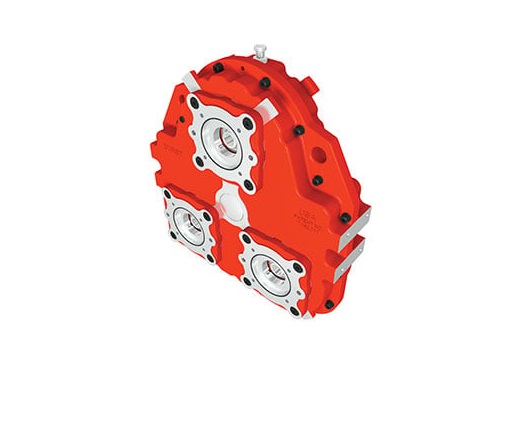

Durst® Pump Drives is a leading modular design hydraulic pump drive solution that can be easily configured to meet your application needs. Our patented pump pad design keeps oil flowing through the bearing.

Parallel Shaft Gearing

Built for longer service life with an integral high-speed pinion, fully supported by bearings within the gearbox. Ultramite is motor-independant allowing the use of standard NEMA C-face or IEC motors.

Parallel Shaft Gearing

The gear drive that delivers reliability, keeps maintenance costs down, maximizes uptime and utilizes the latest technology; the Falk V-Class outperforms and outlasts the competition.

Parallel Shaft Gearing

Designed for improved strength and performance and precision manufactured, Y Unit Gear Drives transmit at higher capacities up to 10,000 hp (and 2.8 million lb-in output torque), without increasing the housing size.

Parallel Shaft Gearing

Grove Gear Parallel Shaft Gearboxes are available in various dimensions and materials to best support your application. From light weight, compact uses to rugged, heavy-duty; Grove Gear has a solution for you.

Parallel Shaft Gearing

Hub City Parallel Shaft Gearboxes include rugged housing and high strength to protect uptime. Three input modes allow for integrating with hydraulic or electric motors or externally coupled drive sources.

Parallel Shaft Gearing

Milwaukee Gear™ Transfer Cases are heavy-duty and engineered to meet the rugged operational demands of a wide range of mobile off-highway applications. They are targeted toward use in mobile construction, agricultural, forestry and mining equipment.

Parallel Shaft Gearing

TDS Parallel shaft speed reducers provide high torque capability and proven dependability. Type TDS standard features include through hardened single helical gears, tapered roller bearings, large inspection plates, a positive splash system for lubrication, extra wide bearing spans and center bearing supports.

Tiếng Việt

Tiếng Việt